World-class chemical transformation

The global methanol market has great business potential. Czech scientists have developed a method for its cheap production of methanol from methane. They took the first three steps out of nine on the way to the final application.

When they are at rest, they are comfortable to be around. One is colorless and odorless, and because it is lighter than air, it easily floats to the ceiling in the room. As if it didn't even exist, it's not visible at all. But it is extremely relentless, so if it mixes with the air, a spark is enough and it appears in the worst possible way - it explodes. It can be very dangerous to its surroundings. Let's meet it, it's called methane.

The other is liquid, indistinct, colorless and useful. But beware, you can smell alcohol. This already suggests that it will not be so completely problem-free. And woe to us if we drink it. It is highly poisonous, so confusion with its brother ethanol can end tragically. It's methanol.

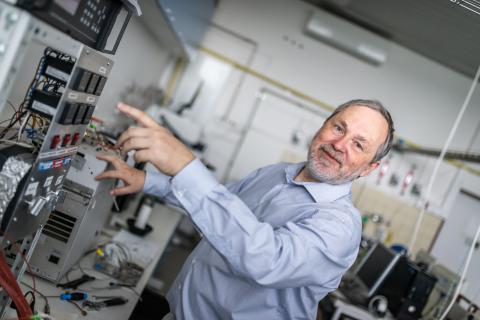

In addition to the fact that both methane and methanol can radically change their own 'mood', they have another important feature - methane can turn into methanol. The scientific team: Jiří Dědeček, Edyta Tabor and Štěpán Sklenák from the J. Heyrovský Institute of Physical Chemistry of the Czech Academy of Sciences created and described a unique way to achieve this. If the phenomenon can be transferred to industrial production, methanol will be produced in a new way and cheaper than before. It would be a scientific application of international importance.

More effective than enzymes

Methane is a major component of natural gas, is inexpensive, and readily available in large quantities. On the way from the well to the end customer, however, it usually goes a very long way. During mining and transport, part of it escapes into the atmosphere. A significant greenhouse gas thus contributes to global warming. However, methane combustion alone has half as much carbon dioxide emissions as coal. It would be advantageous if it was converted to a liquid immediately after extraction, because the liquid can be transported and stored without major difficulties. However, so far this is only possible through demanding and expensive processes. Methane is mainly used as an energy source, it is still waiting for further use.

Methanol is currently produced from so-called synthesis gas, which is a mixture of carbon monoxide and hydrogen, for the production of which natural gas or petroleum residues can be used. This method is impractical and energy intensive. There is no catalyst that converts methane directly to methanol via reaction with molecular oxygen with satisfactory efficiency. However, Jiří Dědeček’s team for the production of methanol from methane created and described new reaction centers that can activate oxygen in a hitherto unknown way - to split it. It is then used to oxidize methane to methanol. Direct oxidation with molecular oxygen is a way to reduce costs and facilitate the production of methanol, or even the production of new fuels.

Two transition metal cations, such as iron, are used to break down oxygen; the cations are placed at a distance of about 7 x 10-7 of a millimeter. A material called zeolite plays a crucial role here, which makes it possible to create such a structure, which is also accessible to oxygen and methane molecules. It is actually a perforated quartz, in which silicon and oxygen atoms form for the bonded structure of channels and cavities into which smaller molecules can fit. "When reaction centers are present in the channels, zeolites become an ideal material for use in catalysis," says Jiří Dědeček. Their presence is possible due to the fact that a part of the silicon atoms in the zeolite is replaced by aluminum. The material thus acquires a negative charge, which must be balanced by something. For example, metal cations, which form catalytic centers.

Interestingly, the oxidation of methane to methanol also occurs in living organisms, in the production of cellular energy. In this case, methanol is generated only as a waste in the cellular process. Like enzymes, scientists need four electrons and two cations to activate an oxygen molecule. But researchers have them much further apart, so they rupture oxygen. From a scientific point of view, this phase is the most interesting. "In some cases, a man-made method may be more effective for a given purpose. This is a world novelty. This procedure has not yet been described in the literature. This oxygen is very reactive, so it can oxidize methane at room temperature," the researcher explains.

So far, the research has been conducted at normal temperatures, which is disadvantageous for the application of the technology in real condition. In practice, it will work at 100 to 200 °C. The higher the temperature, the better the oxygen molecules splits. However, it is necessary to find the optimal temperature for the cleavage of oxygen, because during the first step, oxygen must bind to the system, and this is going on more heavily with increasing temperature. First, however, it is necessary to prepare or find a suitable zeolite that will have as many active centers as possible. Then select the most suitable cations.

Among the big players

In industrial practice, the methane conversion cycle must be repeated many times per hour to produce as much methanol as possible. Extreme care must be taken during this process, as there is a risk of explosion when handling oxygen and methane. The system designed in this way must then work for a long time, perhaps half a year. So far, the tests have been conducted on a small scale and for a limited time. Even so, it is clear that research has big potential to be put into practice. Jiří Dědeček praises that his team is already much better off than other researchers who have tried something similar in the past. However, there is still a long way to go to a possible successful application. The Technology Transfer Center of the CAS takes care of its simplification. It has created a booklet in English that highlights the commercial potential of the technology. Negotiations with potential partners have already taken place. The aim is to apply the scientific result in the form of a license and find funding for so-called proof of concept research. During the proof of concept research, the technology is tested on an industrial scale by giant refineries. This would be proof that the theoretical assumptions can be used in practice.

"A compact and simple method of converting cheap methane into much more useful methanol has huge potential and a great chance to get partners who will contribute financially to the completion of the research," describes Jiří Kavan from the Technology Transfer Center of the CAS. "We are looking for investors mainly among manufacturers of catalysts and related technologies, but also among the largest players in the petrochemical industry and mining companies."

The maturity of a certain technology for the application is indicated by the TRL (technology readiness levels) methodology, which has nine levels. The conversion of methane to methanol proposed by scientists from the Czech Academy of Sciences is now in its third phase. This means that it is verified on a laboratory scale and awaits applied research that will focus on the technical capability of the invention. The end use in the industry could then - if all goes well - could take place in five to ten years. However, the Czechs are not the only ones solving a similar research task in the world.

Three scenarios

There are basically three possible directions for the future. It may turn out that converting methane to methanol will be so expensive that it is not worthwhile. Or it will be expensive, but still cheaper than current methanol production. Or - at best - it will be so cheap that it would be worthwhile to convert a large part of the natural gas to methanol. "The last two variants represent significant economic potential. We need methanol. At the same time, there are reserves of methane on Earth, so why not use them in this way," Jiří Dědeček explains.

The global methanol market is very attractive for business and analysts predict further growth. In terms of methanol consumption, China is currently in the first place, using it in the chemical industry. Methanol is used to make solvents, antifreeze additives, fuels, formaldehyde, formic acid and acetic acid, and many other substances and materials. Methanol consumption is expected to increase significantly over the next twenty years.

If it is very cheap, it could be used to a greater extent as fuel for cars. Making methanol available to a wide range of motorists, however, should at least have an important drawback. As the characteristics in the introduction to the article revealed, it is highly toxic. Any confusion with drinking fluid is even more dangerous than with gasoline.

Text: Jan Klika, Czech Academy of Sciences

Photo: Jana Plavec, Czech Academy of Sciences

Wednesday, June 30, 2021 - 10:00

Translated with the financial support of the Capacity Development of ÚFCH JH, v.v.i. for Research and Development project; CZ.02.2.69/0.0/0.0/16_028/0006251; European Structural and Investments Funds, Operational Programme Research, Development and Education.